Coating the powder surface by changing the cyclone vortex

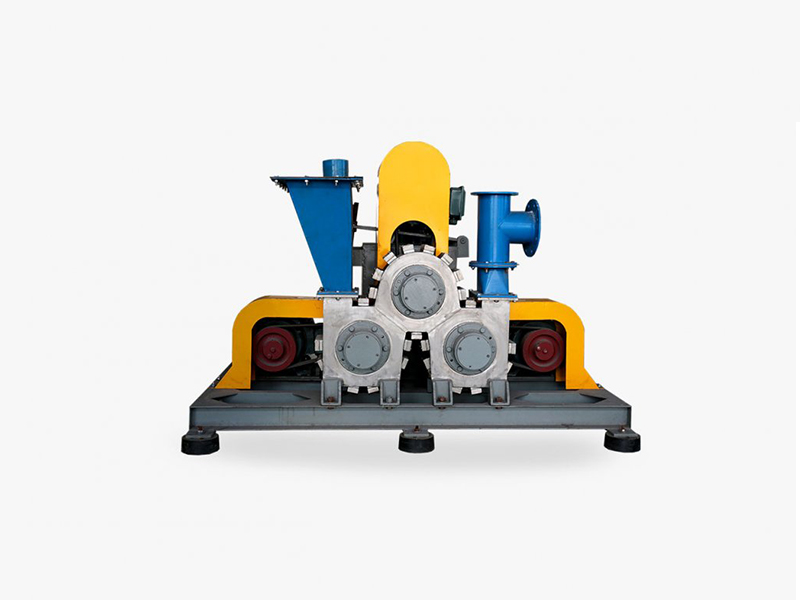

Product description

The relative motion of three rotors can change the effect of cyclone and eddy current to realize the coating of powder surface. Without heating device, it has the advantages of low investment and low operation cost.

Performance characteristics

Working principle

Technical parameter

| Parameter / Model | 300/3 | 600/3 | 900/3 |

|---|---|---|---|

| Speed of grinding disc (rpm) | 5050 | 2580 | 1850 |

| Linear speed of grinding disc (m/s) | 77.4 | 85.1 | 87.2 |

| Grinding motor power (kW) | 3×18.5 | 3×37 | 3×37 |

| Air volume (m³/h)(max) | 2000 | 6000 | 9000 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above parameters are for reference only, please consult our engineers for details.

TAGS