Use conical rotor and stator, the gap between the rotor and stator can be adjusted; the linear speed of the rotor can reach 120m/s; the high-speed impact, shear and friction of materials between the rotor and stator complete the coating process.

Product description

The powder coating machine employs conic rotor and stator, the gap between them can be adjusted.

the powerful vortex flow field, the linear speed of the rotor can reach 120 m/s, which is especially suitable for the dispersion, reduction and crushing of agglomerated materials.

The powder surface modification will be completed by high-speed impact, shear and friction of materials between stator and rotor driven by a motor.

Performance characteristics

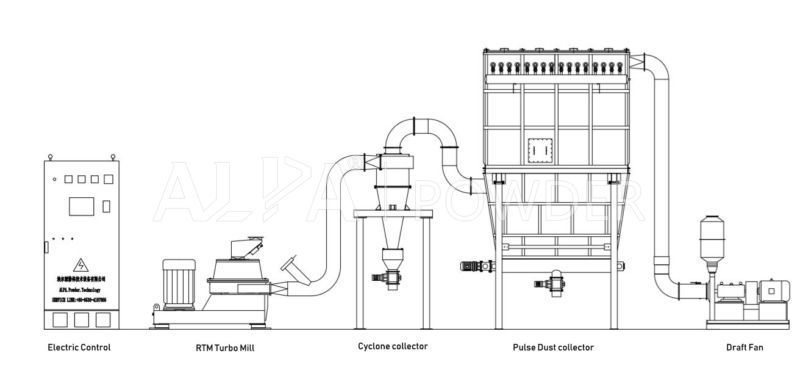

Working principle

The material is uniformly fed into the grinding zone by feeding system and strongly impacted by the high-speed rotating grinding disc. The grinding rotor is composed of a multi-layer grinding disc and a plurality of grinding blades, the material is subjected to various grinding forces such as shearing, collision, friction etc and finished grinding. The qualified materials are collected into the collection zone with the ascending airflow, the coarse materials are returned to the grinding zone for secondary grinding.

Technical parameter

| Parameters/specifications | Rotor Diameter(mm) | Power (kW) | Rotate Speed(Max r/min) | Maximal Air Volume(m3/h) | Fineness(μm) | Output(kg/h) |

| RTM-300H | 300 | 18.5~22 | 7550 | 1600 | 5~250 | 30~800 |

| RTM-500H | 500 | 45 | 4700 | 2400 | 5~250 | 80~2000 |

| RTM-750V | 750 | 55~75 | 3000 | 3600 | 5~250 | 100~3000 |

| RTM-1000V | 1000 | 90~110 | 2250 | 4800 | 5~250 | 200~4500 |

| RTM-1250V | 1250 | 110~132 | 1800 | 6000 | 5~250 | 300~6000 |

TAGS